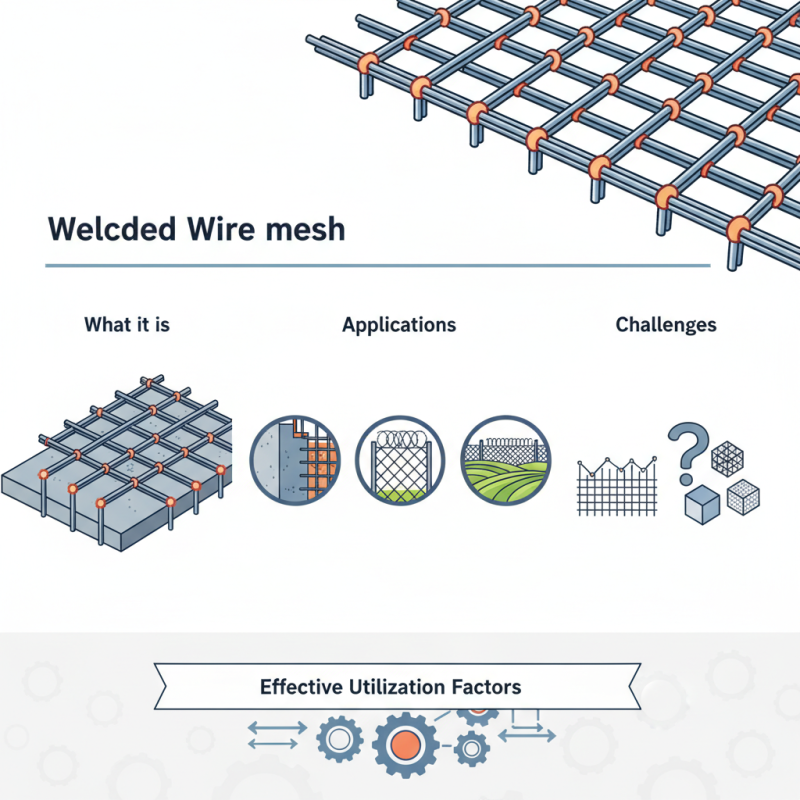

What is welded wire mesh and its applications?

welded wire mesh is an essential material used in construction and various industries. Renowned expert Dr. John Smith, who has over twenty years of experience, states, "Welded wire mesh offers strength and durability that traditional materials simply cannot match." This versatile product is made from steel wires welded together, forming a grid that can support heavy loads.

Applications of welded wire mesh are vast. It is commonly found in concrete reinforcement, fencing, and agricultural uses. The excellent binding properties ensure stability and longevity in structures. In addition, its adaptability allows it to be used for creating custom shapes and sizes for specific projects.

However, the industry faces challenges. Quality control can vary, leading to inconsistencies in final products. Some users overlook the importance of selecting the right mesh type for their needs. As a result, they encounter issues that could have been avoided. Understanding these factors is crucial for anyone looking to utilize welded wire mesh effectively.

What is Welded Wire Mesh? Definition and Composition

Welded wire mesh is a type of fencing and reinforcement material made from intersecting steel wires. These wires are welded together at their intersections, forming a grid-like pattern. Typically, the wires range from 1.2 mm to 6 mm in diameter, depending on the application. The mesh is used extensively in construction, agriculture, and industrial settings. In Europe alone, the welded wire mesh market is projected to reach $3.5 billion by 2024, driven by its versatility and strength.

The standard composition of welded wire mesh includes low-carbon steel, which provides good tensile strength and ductility. Some variations may include galvanized coatings for added corrosion resistance. A common application of welded wire mesh is in concrete reinforcement. It prevents cracking and enhances structural integrity. Additionally, it is widely used in livestock fencing, ensuring safe and secure enclosures for animals. However, the quality of materials can vary significantly, impacting durability and stability.

In many projects, using subpar welded wire mesh has led to costly repairs. The importance of sourcing high-quality materials cannot be overstated. Regular inspections and adherence to industry standards can help mitigate risks. Experts recommend conducting thorough research and reviewing specifications before purchasing to avoid these pitfalls. While welded wire mesh is reliable, one must remain vigilant about its limitations and potential failures in specific environments.

Historical Development of Welded Wire Mesh in Construction

Welded wire mesh has evolved significantly since its early days. Initially used for simple fencing, it has become a cornerstone in modern construction. By the 20th century, its properties made it indispensable for reinforcing concrete structures. According to industry reports, the global welded wire mesh market was valued at approximately $4.5 billion in 2021 and is expected to grow steadily over the next decade.

The applications are vast, from residential buildings to large-scale infrastructure. It provides structural support and enhances durability. In highway construction, it serves as a vital component to ensure long-lasting pavements. The mesh is not only about strength; it allows for flexibility and creativity in design, a testament to its indispensable role in architecture.

Tip: Consider using welded wire mesh in smaller projects too. It offers reliable support without the high costs of traditional reinforcement methods. Remember, overlaying it with other materials might lead to better aesthetic outcomes, though it may complicate construction. Being aware of these details can impact the quality of your build.

Welded Wire Mesh Usage Over the Years

Key Manufacturing Processes and Standards Applied in Production

Welded wire mesh is a versatile product used across various industries. The manufacturing process involves precisely welding wires at intersections, creating a grid structure. The materials commonly used are steel and stainless steel, providing strength and durability. According to the latest industry reports, the global welded wire mesh market size was valued at about $5.5 billion in 2022, with projections indicating steady growth.

Quality standards are vital in the production of welded wire mesh. Compliance with ASTM and ISO standards ensures that the mesh meets safety and performance requirements. This includes factors like tensile strength and corrosion resistance. However, not all manufacturers adhere to these standards. Some may cut corners, leading to product failures that could compromise safety.

Major Applications of Welded Wire Mesh in Construction and Industry

Welded wire mesh is a versatile material widely used in the construction and industrial sectors. Its strength and durability make it a preferred choice for a variety of applications. According to industry reports, the demand for welded wire mesh is projected to reach USD 5 billion by 2025, highlighting its critical role in modern infrastructure.

In construction, welded wire mesh serves multiple purposes. It is commonly used in concrete reinforcement, providing tensile strength to structures. This increases the stability of slabs and walls. Enhanced load-bearing capacity is vital, especially in high-rise buildings and bridges. Additionally, it plays a key role in fencing and enclosing areas, ensuring security and safety in urban developments.

The industrial sector also benefits significantly from welded wire mesh. It is utilized in manufacturing processes such as filtration and screening. This enables efficient sorting of materials and prevents contamination. Some factories, however, have faced challenges with mesh degradation over time. Regular inspections are crucial to maintain effectiveness and ensure worker safety. Neglecting these factors can lead to operational setbacks.

Advantages and Limitations of Using Welded Wire Mesh in Projects

Welded wire mesh is popular in various construction projects. Its sturdy structure makes it ideal for reinforcing concrete. However, there are both advantages and limitations to consider.

One significant advantage is strength. Welded wire mesh provides excellent support, reducing the risk of cracking. It is also easy to install, saving time on projects. The uniform spacing of wires ensures even distribution of weight. This consistency is crucial for stability. Additionally, it is resistant to corrosion when coated, which enhances its lifespan.

On the downside, welded wire mesh can be cumbersome. Handling large sheets may require extra labor. Moreover, it is less flexible than other reinforcement options. This rigidity can pose challenges in certain applications. Adjusting the mesh on-site may become a necessity, leading to delays. Also, its cost may be higher compared to alternatives in some cases. It's important to weigh these factors before making a decision.